Our team of technical specialists have been involved in PLC retrofitting of Allen Bradley and other control systems on gas turbine packages.

We can assist with all Makes of controllers to achieve to your desired control solution.

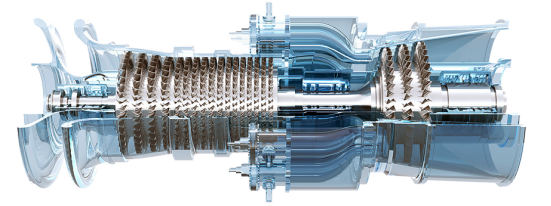

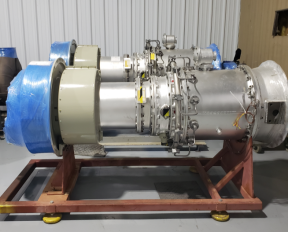

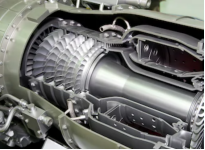

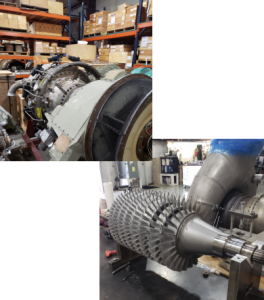

- We specialize in Light Industrial Gas Turbines, Diesel Engines & associated balance of plant equipment.

- Gas compressor packages & DGS.

- Diesel engine driven packages

- Pump skids & packages

- Alternator packages

- We support all ancillary equipment & related systems such as gearboxes & WHRU’s

Through our association with Rockwell Automation, all Rockwell & Allen Bradley equipment can be procured at reasonable rates and made application to your application.

Critical Spares evaluation to ensure reduced downtime

Supply of spares & equipment for all gas turbine packages

Part remanufacture facility (including reverse engineering for DGS assemblies redial & thrust bearing assemblies)