Black Iron Energy – engineering solutions for your rotating equipment from experienced OEM trained engineers and technicians.

We target problems by providing solutions on rotating equipment and plant imbalances by applying investigative engineering techniques and not simply replacing parts until the problems ceases.

Our innovative solutions all have engineering principles as the base for design and are risk assessed to ensure safe implementation.

WE COVER THE FOLLOWING WORKSCOPES:

- Construction, commissioning & start up.

- Semi annual and annual services.

- Mechanical services.

- Control system upgrades / retrofits.

- Detailed procedures to allow auditable trail of work completion.

- RCFA (Root Cause Failure Analysis).

PROCESS PLANT ROTATING EQUIPMENT OPTIMISATION

- Vibration analysis (driven equipment, gearbox& diesel engine & turbine)

- Preventative and predictive maintenance.

- Encode all issues for lessons learnt (From cause to remedy).

- Package assessments and associated reporting templates to industry standards.

- Critical spares management Rolls Royce, Rockwell Automation & Wartsila).

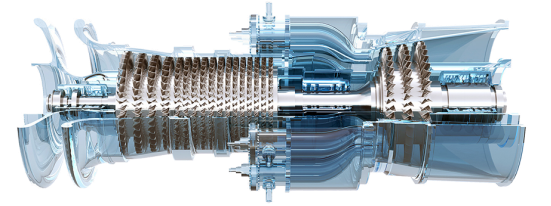

- We specialize in Light Industrial Gas Turbines, Diesel Engines & associated balance of plant equipment.

- Gas compressor packages & DGS.

- Diesel engine driven packages

- Pump skids & packages

- Alternator packages

- We support all ancillary equipment & related systems such as gearboxes & WHRU’s

Supply of reciprocating and rotary screw compression application engineering and construction/install services for all Major OEM’s including Ariel, Gemini, GE, Frick, Sullair, Howden, etc.

- Pulsation, vibration, and torsional engineering analysis

- Detailed performance including load optimization

- Recommendations on compression selection and solutions

Complete Field Retrofit Solutions

- System redesign including re-cylinder, engine and compressor changes

- Construction services of process piping and pressure vessels.

- Cooler sizing and bundle replacements

- E&I and control system updates

- VDC (virtual design and construction) 3D scanning

- Comprehensive design services – Layout drawings and PIDS

Ability to supply new and used components for a range of applications

- Compressor and Engine Parts

- Pumps seals and critical spares

- Motors

- Valves, PSVs and meters

- E&I including pressure, temperature and flow measurement

- Solenoids and actuated valves

- Engine and compressor replacement parts and spares

- Caterpillar, Waukesha, Superior, Solar, GE, MTU, IR and Others

- Ariel, Gemini, Superior Ajax, IR, Worthington, Frick, Howden, Sullair, Others

Parts, critical spares and stocking programs

- Consignment stocking programs

- Customer stocking programs on location or central warehouse

- Quick deployment

A large surplus components component and parts inventory held by Black Iron ensures quick assess and deployment at discounted prices.

Black Iron OEM and aftermarket relationships ensure a one-stop-shop for a solution to any need.

- Saturn 10/20.

- Centaur 40/50.

- Taurus 60/70 (CONVENTIONAL & SOLONOX).

- Mars 90/100 (CONVENTIONAL & SOLONOX).

- Titan 130(CONVENTIONAL & SOLONOX).

- SGT 100

- TB5000

- SGT700

- GE Frame 5

- Siemens ADGT (Rolls Royce)

- Package & equipment alignments (dial gauge & laser)

- Gas turbine package refurbishments, retrofits and modifications

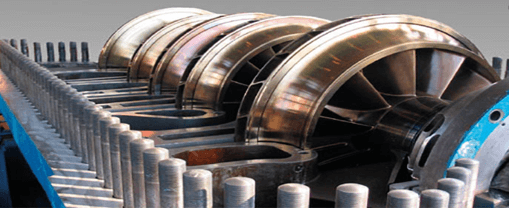

- DGS, WGS, radial & thrust bearing exchanges, replacement & refurbishments

- DGS, WGS & compressor flushing

- Gas compressor bundle replacements

- Vibration measurement & analysis

Control System

Through our association with Rockwell Automation, all Rockwell & Allen Bradley equipment can be procured at reasonable rates and made application to your application.

Control Values

Supply of spares & equipment for all gas turbine packages.

Spares Evaluation

Critical Spares evaluation to ensure reduced downtime.

Remanufactured

Part remanufacture facility (including reverse engineering for DGS assemblies redial & thrust bearing assemblies)